- 1.Machine adopts Siemens PLC control, all data can be display in the touch screen.

- 2. Numerical control servo cutter device, high precision cutting;

- 3. Automatically cut, automatically fall pipe, automatically change speed and revert;

- 4. Round knife cutting, incision more smooth, performance more stable;

- 5. With online multi-cut blades, no need secondary cutting, save labor and time.

- 6. Stainless steel gluing box, with polyurethane scraper and high carbon steel plastic knife, durable in use;

- 7. Machine adopts Flange for fix the mandrel.

- 8. Machine supply of lubricant automatically.

- Die Cutting Machine

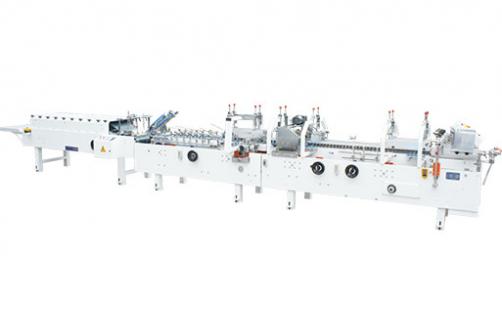

- Folder Gluer

- Film Laminator

- Flute Laminator

- Guillotine

- Hot Stamping Machine

- UV Coating Vanish Machine

- Paper Folding Machine

- Envelope Making Machine

- Case Making&Cardboard

- Slitting Machine

- Book Binder

- Punching&Drilling Machine

- Wire Stitching

- Embossing Machine

- Paper Tube Machine

- Paper Bag Making Machine

- Paper cutting machine

|

Raw material |

Surface paper: 60g; bottom paper: 120g +120g |

|

Number of roller |

1-3 layer |

|

Tube diameter |

5-10mm |

|

Tube wall-thickness |

0.3-1 mm |

|

Cutting Length |

100-800mm |

|

Winding head |

2 |

|

Power |

7.7KW |

|

Cutter |

5 sets |

|

Operator |

1-2 person |

|

Winding speed |

0-42 m/min |

|

Speed control |

Frequency |

|

Working Air Pressure |

0.6Mpa |

|

Power Supply |

380V/3Phase/50Hz |

|

Measurement |

5600*1600*1750mm |

|

Working Space |

11000mm * 6000mm*2000mm |

|

Weight |

2000kgs |

|

Driving system |

|

|

Main motor |

3 KW |

|

Servo motor |

1 KW (Yaskawa) |

|

Frequency inverter |

3.7KW |

|

Control system |

|

|

PLC controller |

China Research |

|

Touch screen |

Weinview |

|

Fix length way |

Encode |

|

Pneumatic Components |

Airtec |

|

Electric Components |

Schneider |

|

Equip device |

|

|

Paper shelf type |

Integral reel stand |

|

Auto fall tube shelf |

Have |

|

Glue shelf |

Have |

|

Belts |

2 |

|

Core mould |

1 |

|

Tool box |

1 |

|

Spare Knife |

10 pcs |

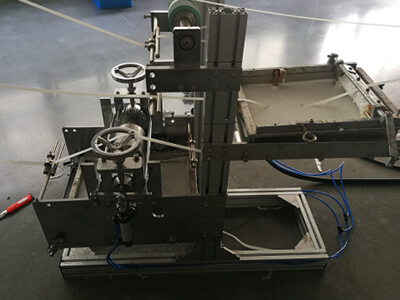

Paper Straw Making Machine

Paper Straw Making Machine

RHXG Model Paper Straw Machine(avan)

RHXG Model Paper Straw Machine(avan)