- Die Cutting Machine

- Folder Gluer

- Film Laminator

- Flute Laminator

- Guillotine

- Hot Stamping Machine

- UV Coating Vanish Machine

- Paper Folding Machine

- Envelope Making Machine

- Case Making&Cardboard

- Slitting Machine

- Book Binder

- Punching&Drilling Machine

- Wire Stitching

- Embossing Machine

- Paper Tube Machine

- Paper Bag Making Machine

- Paper cutting machine

|

Model |

AEM-1080T |

|

Max. Paper size |

1080*780mm |

|

Min. Paper size |

400*330mm |

|

Max.die cutting size |

1075*770mm |

|

Die frame inner size |

1100*790mm |

|

Cutting plate size |

1080*780mm |

|

Max. Foil stamping size |

1060*760mm |

|

Min gripper needle size |

7mm |

|

Cutting precision |

≦±0.1mm |

|

Foil stamping precision |

≦±0.125mm |

|

Max. cutting pressure |

300T |

|

Max. cutting speed |

7000s/h |

|

Max. Foil roll diameter |

Ф250mm |

|

Vertical foil roll width |

15-1060mm |

|

Horizontal foil roll width |

15-760mm |

|

Vertical foil roll shaft |

3pcs |

|

Horizontal foil roll shaft |

2pcs |

|

Controllable temperature area |

12pcs |

|

Temperature range` |

50-199℃ |

|

Pre-stacking height |

1550mm |

|

Collection stack height |

1400mm |

|

White board |

0.1-2mm |

|

Corrugated paper |

<4mm |

|

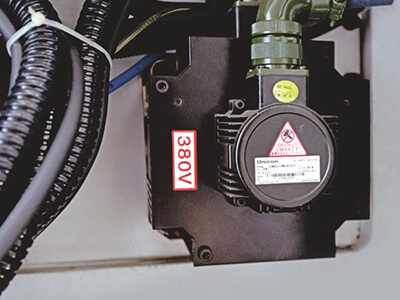

Main motor power |

11Kw |

|

Heating area power |

24Kw |

|

Total power |

60Kw |

|

Weight |

18T |

|

Dimension |

5880*2550*2680mm |

-

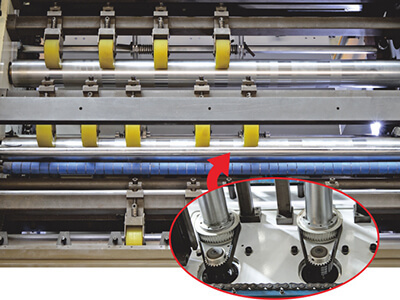

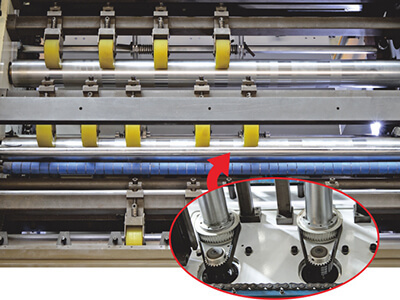

1.Foil device adopt high wear-resisting polyurethane, ensures stable and reliable running

-

2.Dual foil detection system to check on real-time

-

3.Separate foil recycle device mixed recycle box to make operation fast and easily

-

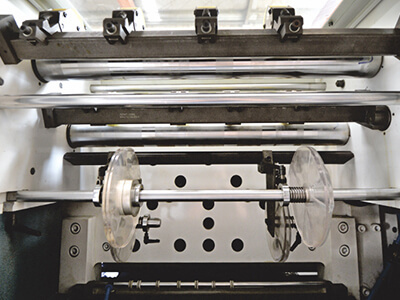

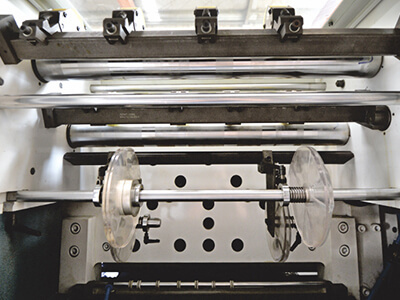

4.Foil holder with movable design, can push out of machine for place the foil easily and fast

-

5.Adopt transverse foil placement device, easy and convenient

-

6.Static elimination device to make paper smooth and accurate

-

7.Longitudinal foil roll with rational distribution and servo drive

-

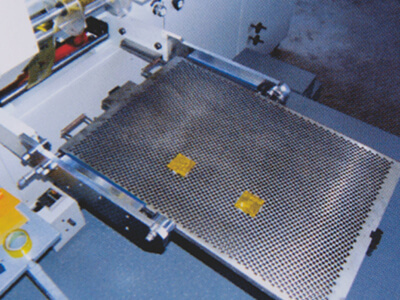

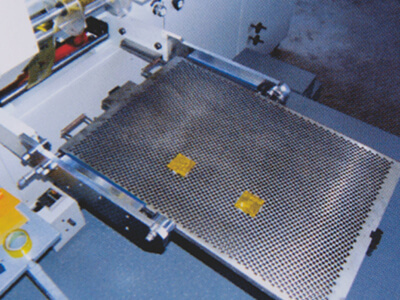

8.The honeycomb board made by special material and special processing, helps locating the stamping board

-

9.Manual foil wearing device greatly shorten the installing time

-

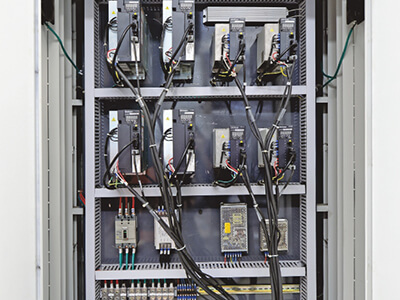

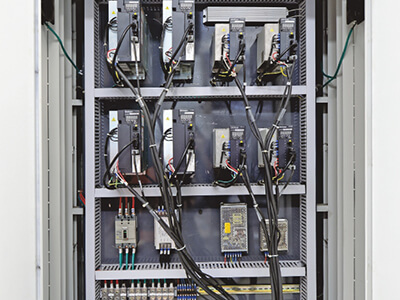

10.High performance servo control system with high stability and anti-interference performance

-

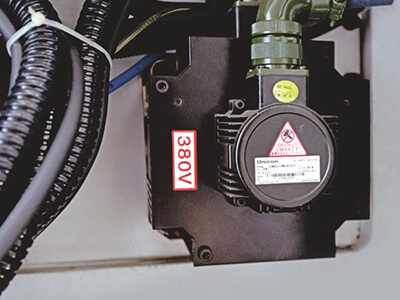

11.4Kw longitudinal foil turning servo motor, moving foil stable and reliable

-

12.Four air intake and four air outlet in paper feeder and operate the thin and thick paper with high precision

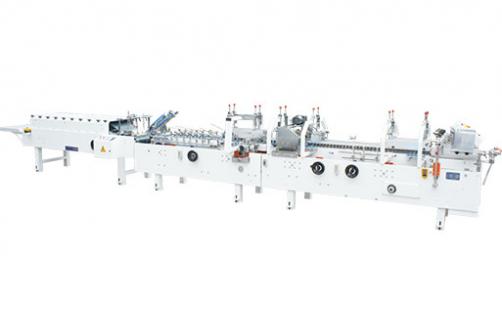

TYMK-750 Dual-use Hot Stamping and Die Cutting Machine

TYMK-750 Dual-use Hot Stamping and Die Cutting Machine