- Die Cutting Machine

- Folder Gluer

- Film Laminator

- Flute Laminator

- Guillotine

- Hot Stamping Machine

- UV Coating Vanish Machine

- Paper Folding Machine

- Envelope Making Machine

- Case Making&Cardboard

- Slitting Machine

- Book Binder

- Punching&Drilling Machine

- Wire Stitching

- Embossing Machine

- Paper Tube Machine

- Paper Bag Making Machine

- Paper cutting machine

|

Technical Parameter |

Control System |

|||

|

Paper Layer |

2-5 layers |

Motor |

3.0kw |

|

|

Inner Diameter |

5-10mm |

PLC |

Samkoon(specialized for paepr straw making machine) |

|

|

Wall Thickness |

0.5-1mm |

Touch Screen |

Samkoon |

|

|

Winding Speed |

0-45 meters/min |

Inverter |

3.7kw |

|

|

Winding Nose |

Two noses single belt |

Execute Components |

CHNT |

|

|

Cutting Length |

100mm-800mm |

|||

|

Length fixing |

Encoder |

Signal Components |

Hugong |

|

|

Speed Control |

By Inverter |

Pneumatic Components |

Xingchen |

|

|

Cutting System |

Numerical Multi-blades (standard 5 sets) |

Electric Components |

CHNT |

|

|

Synchronism tracking cutting system |

Servo motor synchronism tracking |

Bearing |

Haerbin |

|

|

Servo Motor |

Yaskawa 1kw |

|||

|

Gluing Way |

Single/Double sides |

Screw Rod |

ABBA from Taiwan |

|

|

Operator |

1-2 person |

Slider |

ABBA from Taiwan |

|

|

|

|

|||

|

Working Air Pressure |

0.6Mpa |

Configuration |

||

|

Power Supply |

380V/3Phase/50Hz |

Paper Reel Stand |

3 Layers Cross Type |

|

|

|

|

Gluing Unit |

3 Layers Spraying Type |

|

|

Measurement & Weight |

Belt |

2 Pieces |

||

|

Measurement |

5600*1600*1750mm |

Mandrel Shaft |

2 Pieces |

|

|

Working Space |

11000mm * 6000mm*2000mm |

Blades |

5 pcs |

|

|

Weight |

1200kgs |

Useful Tool |

1 Set |

|

|

Application Material |

|

|

Main |

|

|

|

|

|

|

|

|

|

|

-

Cutting Head

-

Unwinder Stand

-

Control Panel

-

Oil Tank

-

-

Glue Details

-

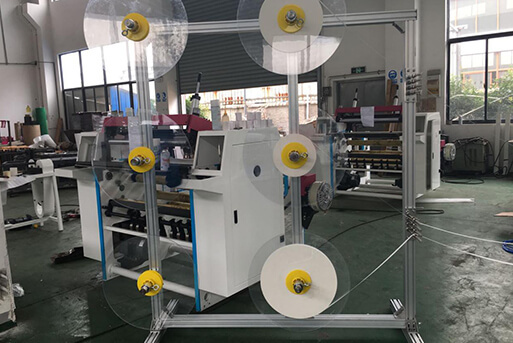

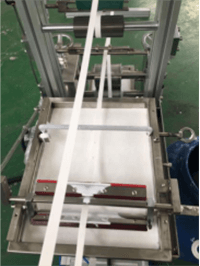

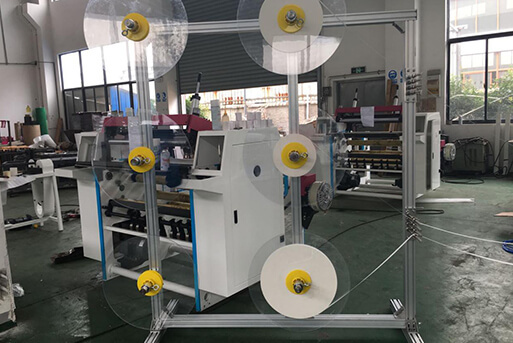

RHXG Model Paper Straw Machine(avan)

RHXG Model Paper Straw Machine(avan)

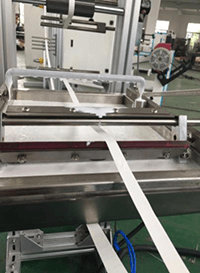

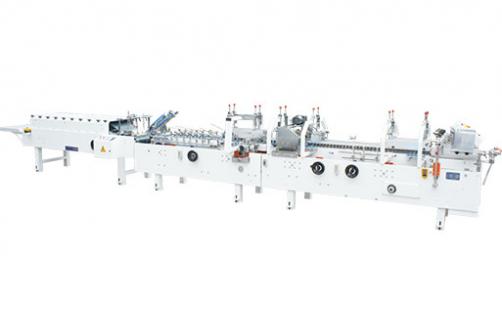

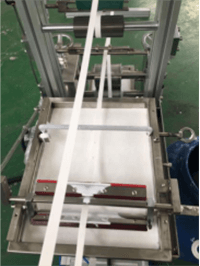

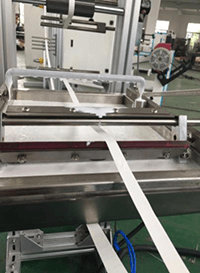

ZGJ-D Paper Straw Machine

ZGJ-D Paper Straw Machine