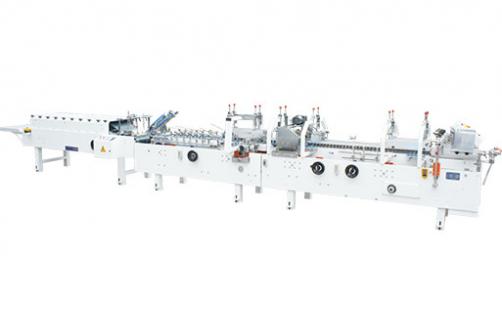

The PRY-350G flexo press is a pay-back investment for any company looking for high productivity, efficiency and astonishing printing results. PRY-350G by PRINTYOUNG is a top-class press, capable of producing the most complex and creative label designs on a variety of substrates and offering a whole range of printing and finishing.

Its characteristics of short web path, perfect registration at the highest speeds and general ease of use and involve large time savings during start-up and considerably reduce general wastage. This label printing press inner stability is synonymous of high precision, printing consistency and reduced maintenance.

The PRY-350G narrow web press is the ideal press integrating any printer’s equipment whose dream is to be competitive on an extended product including pressure-sensitive labels, shrink sleeves, in-mold labels, flexible packaging and special applications.

Main Features

1.Latest servo control system.

2.Gearless/shaetless flexo

3.Advanced sleeve technology

4.Water Chiller drum

5.Short web path

6.Minimum ink quantity to start printing

7.Operator-friendlyTechnical Parameters

|

Max Printing Speed |

180m/min |

|

Printing color |

4-12colors |

|

Max. web length |

340mm |

|

Max. printing width |

350Gmm |

|

Repeat length |

Z76-190 (241.3mm-603.25mm) |

|

Max. unwinding diameter |

900mm |

|

Max. rewinding diameter |

900mm |

|

Power supply |

380-400V, 3P, 50/60Hz |

|

Dimensions(L×W×H) |

1083×1560×1520mm (8colors) |

1.Unwinder with pneumatic lift (Max. dia.: 900mm)

2.Air shaft (3 inches)

3.Air in/off switch

4.Magnetic powder brake control

5.Automatic tension control

6.Automatic stopping system for lacking of material

7.web guiding system

8.material forwarder (Nip) by servo motor

1.Super flexo printing unit

2.Printing roller driven by independent servo motor

3.Sleeve technology

4.Anvil roller (free type)

5.Water driller drum driven by independent servo motor

6.Automatic cooling circulatory system

7.Operation panel for fine adjustment with self - locking function

8.Fine pressure adjustment for the bearer

9.2nd pass registration sensor

10.Easy take-off anilox roller

11.Easy take-off ink tray, auto up/down

12.Movable touch screen (easy operation)

13.Guard line for whole machine

1.driven by independent servo motor

2.Left-right and forward-backward registration control

3.Die-cutting roller lifter (easy load and take off)

4.Snow ball type matrix, with magnetic device, rewinding motor and inverter

1.Driven by two servo motors

2.Sheeter conveyer

3.Counting function

1.Movable rotary screen printing unit

2.STORK or WTS is for optional

3.Without UV dryer

1.fan cooler, 5.6KW/unit

2.Independent power control for each UV dryer

3.Power auto changing according to printing speed

4.Auto Control with UV exhaust

5.Independent UV control panel

1.Driven by independent servo motor

2.Double rewinders for optional

3.Automatic tension control system

4.Rewinder with pneumatic lift (max dia. 900mm)

4-colors 1000mm CI Type Flexo Printing Machine

4-colors 1000mm CI Type Flexo Printing Machine

4-colors 1000mm High-speed Flexo Printing Machine

4-colors 1000mm High-speed Flexo Printing Machine