Features

- 1. Usage paper : 180~650g/m2 Paperboard

- 2. Box forming: straight line, double side (optional)

- 3. Electric: 4kw, AC380V

- 4. Weight: 2000kg

- 5. Dimension: 7500× 11500×1400(mm)

|

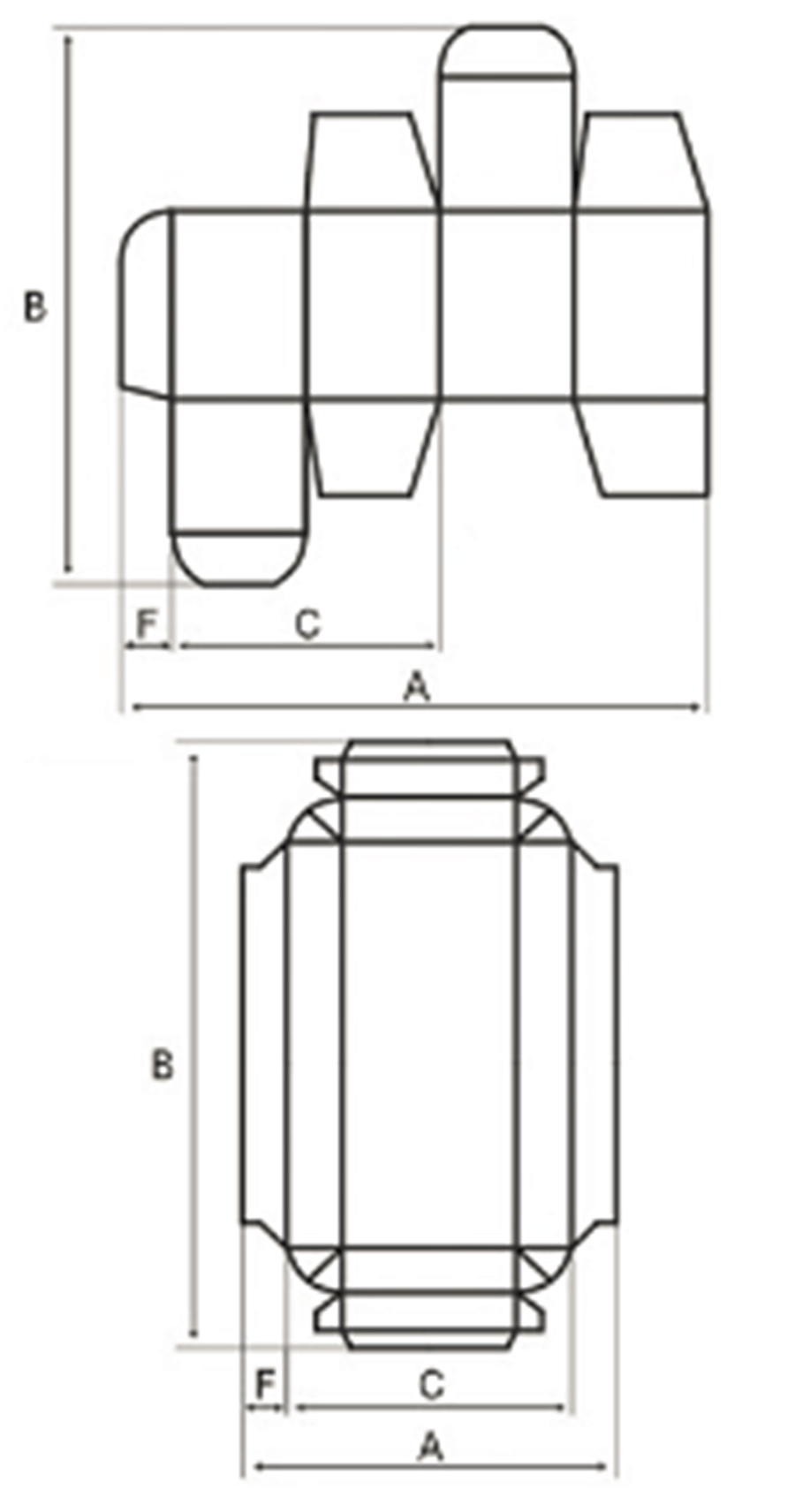

Model |

Box type |

A Max |

A Min |

B Max |

B Min |

C Max |

C Min |

F Max |

F Min |

|

ZH-580Y |

Straight line(I) |

580 |

90* |

500 |

60 |

270 |

80 |

30 |

8 |

|

Double side gluing(II) |

450 |

90 |

500 |

60 |

360 |

70 |

30 |

10 |

|

|

ZH-780Y |

Straight line(I) |

780 |

90* |

500 |

60 |

320 |

80 |

30 |

8 |

|

Double side gluing(II) |

550 |

90 |

500 |

60 |

480 |

70 |

30 |

10 |

|

|

ZH-980Y |

Straight line(I) |

980 |

90* |

500 |

60 |

380 |

80 |

30 |

8 |

|

Double side gluing(II) |

560 |

90 |

500 |

60 |

520 |

70 |

30 |

10 |

1.The whole machine’s steel frame adopts laser cutting, after-punching folding. So the structure is more reasonable, assembling is more accurate and running is more stable.

2.Pre-fold can do 1st line 180 degree, 3rd line 135 degree.

3.After pre-folding, it is suitable for auto packing production line, like medicine box, wine box and cosmetic box.

4.It adopts synchronous belt driving. Synchronous driving is faster, noise-lower and safer.

5.Adopts PLC and frequency speed regulator.

6.It can be applied to duplex board and E/F/N corrugated cardboard.

ZH-600A 700A 800A Automatic Folder Gluer with Pre-fold

ZH-600A 700A 800A Automatic Folder Gluer with Pre-fold

ZH-600G 700G 800G Automatic Muti-functional Crash Lock Bottom Folder Gluer

ZH-600G 700G 800G Automatic Muti-functional Crash Lock Bottom Folder Gluer

ZH-600D 700D 800D High Configuration Crash Lock Bottom Folder Gluer

ZH-600D 700D 800D High Configuration Crash Lock Bottom Folder Gluer