-

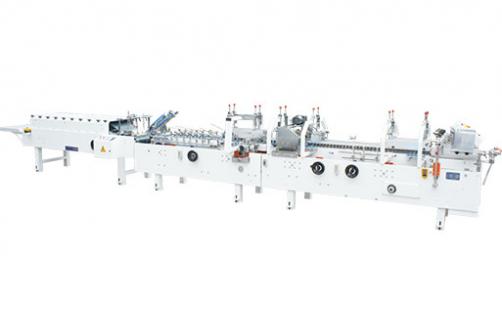

YDFM-A series manual laminating machine is a kind of multi-

functional laminator which is newly developed upon long time

of users’ feedback and market needs. It suits the lamination

of pre-glued film and glueless film. Gluless film lamination

means the machine laminates the glueless film without any

glue on paper directly in a certain temperature and pressure.

This technology is a new green lamination. The whole process

has no any glue thereof, and reduces energy-loss and saves

production costs, and also avoids environmental pollution and

toxic residuum from traditional laminating technology.

The laminated products will be water-proof, durable, of clear

picture and good spatial effect. And the machine is widely

used for the lamination of packing materials, labels, books,

drawings and maps etc.